BNC targets 10 000 tonnes of nickel per annum

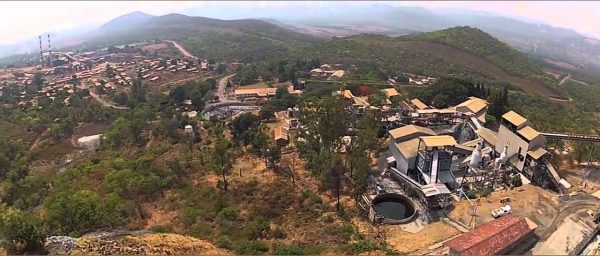

Bindura Nickel Corporation (BNC), is pursuing its goal of producing 10 000 tonnes of nickel per annum backed by a huge resource base at its Trojan Nickel Mine and other mines across the country.

A member of the Kuvimba Mining House, BNC has nickel resources across Zimbabwe under mining, processing and exploration assets. These are Trojan Mine, Shangani Mine, the BSR (formerly Bindura Smelter and Refinery) facility, Hunter’s Road Project, Damba-Silwane as well as the Trojan Hill and Kingstone Hill Projects. Collectively, these resources amount to a total of 71,37 million tonnes of ore, at an average grade of 0,59 percent containing approximately 420,8 kilo-tonnes of nickel.

Chairman Much Masunda has indicated the mining firm will take advantage of the availability of high volume low grade resource availability – approximately 8,33 million tonnes, at an average grade of 0,86 percent at Trojan Nickel Mine, which will support a high-volume strategy.

Additionally, the resources group boasts large and underutilised processing capacity.

“Trojan Nickel Mine has a sound processing plant with approximately 60 percent excess capacity at current production rates. This plant has an installed capacity to process up to 1 million,” said Mr Masunda.

According to the group, Trojan is the only operating unit within BNC and on average produces +/-400 000 tonnes of ore and 5 500 tonnes of nickel in concentrate per annum respectively, which translates into +/- 40 percent plant capacity utilisation.

“The low capacity utilisation has largely been driven by a mining strategy anchored on a high-grade/low-volume ratio of 1 part massive to 2 parts disseminated ore,” said Mr Masunda in an update accompanying group financials for the year to March 31, 2021.

During FY21, ore milled fell 5 percent to 411 754 tonnes, compared to 434 077 tonnes milled in the previous year due to a loss in production, emanating from the pre-planned shutdown, running from the beginning of March to the end of April 2021, to facilitate commissioning of the Re-deepening and Tie-in Project. Head grade, at 1,52 percent was marginally lower than the 1,53 percent achieved in the prior year.

Nickel in concentrate produced decreased 5 percent to 5 363 tonnes on to the lower milled tonnage, lower ore grade and lower recovery achieved respectively.

The Refinery and Shangani Mine remain under care and maintenance.

Nickel in concentrate sold fell 3 percent to 5 496 tonnes in line with the reduced production.

Global nickel prices improved by 7 percent during the period under review, to an average of US$14 999 per tonne which more than compensated for the reduction in sales volume.

Resultantly the group recorded a 13 percent increase in annual turnover to US$59,2 million.

Cost of sales increased by 19 percent to US$44 9 million, compared to US$37,7 million in the prior year mainly driven by the impact on local input costs, of disparities between the auction exchange rates and the exchange rates that suppliers use in their pricing models, as well as the high cost of maintaining the aged mobile mine plant and equipment.

Gross profit margin was lower at 24 percent compared to 28 percent in FY20, although the gross profit amount achieved in the period under review remained constant, when compared to prior year.

Operating profit increased by 17 percent to US$3,3 million attributable to revenue growth driven by improved nickel prices, coupled with the decrease in marketing and distribution expenses, arising from a new off-take agreement entered into during the year.

Profit for the year nearly doubled to US$1,7 million translating to basic and diluted earnings per ordinary share of US0,139 cents and US0,133 cents respectively.

Herald