Implats commits R50bn capex to mines, beneficiation, energy, decarbonisation

Platinum group metals (PGMs) company Implats, which generated free cash flow of R28.8-billion in the 12 months to June 30, said on Thursday that it had allocated R4.3-billion over the next five years to energy security and decarbonisation.

Gross profit totalled R41.3-billion at a gross margin of 35% with earnings before interest, taxes, depreciation and amortisation (Ebitda) of R53.4-billion at an Ebitda margin of 45%.

The Johannesburg Stock Exchange-listed company, headed by CEO Nico Muller, declared a final dividend of 1 050c a share, bringing the total dividend for the 2022 financial year to 1 575c a share.

The company closed the period debt free and with net cash of R26.5-billion excluding leases.

A suite of organic growth projects have been advanced and value-accretive acquisitive growth pursued amid rising input costs, constrained supply chains and labour market tightness particularly in Canada, the impacts of which were compounded by extended safety stoppages, intermittent power supply and periods of community unrest.

Implats is committed to a five-year, R50-billion capital investment programme to extend life-of-mine (LoM) development at several of its operations, increase beneficiation capacity, strengthen energy security and ensure the group meets its decarbonisation targets.

Of this capital investment, R9-billion is earmarked to expand its South African and Zimbabwean smelting and refining facilities.

In addition, around R8-billion will be invested across managed and joint venture South African mining operations over the next few years to extend LoM at producing mines, secure meaningful employment and entrench South Africa’s status as a stable and sustainable global PGMs producer, to support enduring benefits for all stakeholders.

Added to several other LoM extension projects at the Impala Rustenburg operation, Implats is confident of sustaining and growing total refined six element (6E) PGMs supply from its Southern African assets over the next decade.

Projects under study and in implementation at integrated processing assets will benefit the Southern African region’s production, reduce the group’s processing environmental footprint, and directly increase local beneficiation, positioning the region more competitively as a global mine-to-market PGMs producer.

Regarding the R4.3-billion allocated to ensure each operation has renewable energy in the mix to meet decarbonisation targets and strengthen energy security, Impala Canada is already 95% powered by renewable hydropower (5% natural gas), and Zimplats’ energy mix is 50:50 thermal to renewable hydropower.

Zimplats has obtained a 185 MW power generation licence, with the first phase of a solar photovoltaic (PV) project (35 MW, $37-million) in progress. This is the first large-scale project towards meeting the short-term (2030) decarbonisation target of a 30% reduction against the 2019 baseline, and it supports Implats’ stated ambition of achieving carbon neutrality by 2050.

In addition, several studies are underway — 33 MW of solar PV generation is at feasibility stage at Marula, and prefeasibility studies were completed at Impala Rustenburg and Impala Refineries — to establish additional renewable energy capacity of around 300 MW by 2030, with additional capacity possible. These studies are conducted in parallel to Implats’ programme to purchase electricity from independent power producers.

PROPOSED RBPLAT ACQUISITION

In November 2021, the proposed acquisition of Royal Bafokeng Platinum (RBPlat) was launched – a transaction with the potential to transform the outlook of its key western limb assets at Impala Rustenburg, while ensuring long-term sustainable PGMs production and continued economic benefits for the greater Rustenburg area and its communities.

Implats is pursuing the conclusion of the offer process associated with its proposed acquisition of RBPlat, with a key focus on securing outstanding regulatory approval from the Competition Tribunal.

Near-term operational focus is on re-establishing operational momentum at Impala Canada and Impala Rustenburg, ramping up installed milling capacity at Zimplats and Two Rivers and the timeous and cost-effective advancement of LoM extension, growth and environmental projects across its mining and processing assets.

Dollar basket pricing for 6E PGMs was 4% lower at $2 481/oz and rand revenue per 6E ounce sold decreased by 4% to R37 703/oz sold. Palladium and rhodium markets tightened with platinum remaining in surplus.

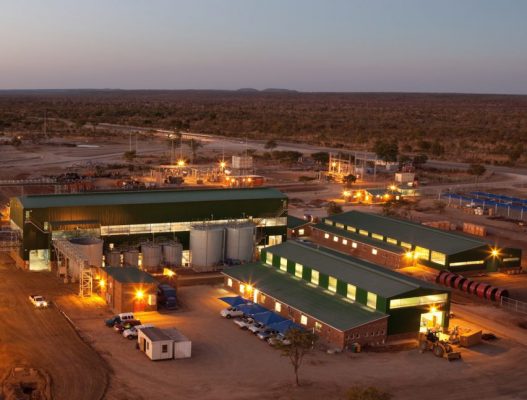

ZIMPLATS’ MINE REPLACEMENT, BENEFICIATION PROJECTS

In November 2021, the board approved the expansion of existing smelter capacity at Zimplats and the installation of sulphur dioxide abatement to mitigate its air quality impacts, at a total capital vote of $521-million. Together with the phased solar projects, this will result in an industry-leading environmental footprint for the Zimbabwean smelting facilities. This expansion will accommodate an additional 600 000 6E PGM ounces a year, the matte from which will be transported to the existing South African processing facilities for further refining.

The $468-million mine replacement projects focused on upgrading Bimha mine and developing the new Mupani mine, progressed well and remain ahead of schedule. Bimha and Mupani will replace the Ngwarati, Rukodzi and Mupfuti mines on their depletion.

The construction of an initial 0.9-million-tonne-a-year module at the third concentrator plant, at $104-million, together with associated additional mining fleet ($18-million) and infrastructure, is on schedule, with commissioning planned in the 2023 financial year.

In addition, studies are underway to refurbish and commission the base metal refinery at Zimplats, affirming its commitment to furthering in-country beneficiation.

IMPALA REFINERIES PROJECTS

The nature and quantum of ore feeds contributing to the group’s PGMs production continues to evolve over time, while ounce production is set to increase in line with Implats’ growth and beneficiation strategy, with R3.9-billion over five years being allocated to improving the South African refining facilities.

About R50-million has been approved to debottleneck sections of the Base Metals Refinery in Springs and expand treatment capacity by 10% in the medium term to provide room for future growth.

In addition, a new precious metals facility is being built, which includes three new processing sections and acquired utilities and ancillary areas. Feasibility studies into further capacity expansions at the South African base and precious metals refineries are also well advanced.

MARULA’S PHASE II EXPANSION PROJECT

The R5.1-billion Marula Phase II project was approved by the board during the year. It serves to replace production as the current Marula LoM depletes and includes a concentrator plant expansion allowing for incremental production growth. The project will deliver a 17-year LoM extension to 2039, with a 20% increase in milling capacity to 2.4-million tonnes a year.

TWO RIVERS’ EXPANSION, TAILINGS PROJECTS

In partnership with African Rainbow Minerals, Implats has committed R5.7-billion over the next five years to construct a new Merensky mine at the Two Rivers operation. The Merensky mining project will expand production by 180 000 6E ounces. Implats has a 46% stake in Two Rivers, but 100% of the 180 000 oz of 6E PGMs project production will be treated through the group’s smelting and refining facilities.

The 40 000-t-a-month upper group two (UG2) plant expansion has been commissioned, with mining rates ramping up to maintain higher annualised feed rates to secure increased ounce production.

Expansion of the tailings storage facility, which facilitates both the UG2 expansion and Merensky project, is nearing completion.

MIMOSA’S NORTH HILL PROJECT

The $90-million North Hill project will extend Mimosa’s LoM by 10 years to 2044 and sustain 227 000 t a month into the existing processing plant. The feasibility study has been completed and presented to the Mimosa board and a memorandum of understanding to support the project execution is under discussion with the Zimbabwean government. A plant optimisation project underway is aimed at improving process recoveries.

IMPALA CANADA MILL DECOUPLING PROJECT

A mill decoupling project at Impala Canada, approved in May 2021, will decouple the semiautogenous grinding mill from the crushing section to optimise the stability of milling capacity throughput and grind.

EIGHT EMPLOYEE FATALITIES

“It is with deep regret that the group reported eight employee fatalities in the year, with seven at its managed operations. The board of directors and the management team have extended their sincere condolences to the families and friends of our lost colleagues, and the group offers ongoing support to their families,” Implats stated in a release to Mining Weekly.

Following investigations in each case, the focus on visible leadership, mining discipline and targeted safety interventions has been renewed. A fatality-free final quarter followed the implementation of heightened safety measures.

SUSTAINABILITY AND ESG

Implats’ aspiration is to become an industry leader in environmental, social and governance (ESG), producing metals that sustain livelihoods beyond mining and create a better future. The groups’ achievements in sustainable development during the year were anchored by a sound environmental and social performance, an increase in capital allocation to ESG projects, and through prioritising safe, responsible, competitive and consistent operational delivery, while applying industry leading ESG practices.

During the year, Implats was honoured to be recognised for its outstanding ESG performance. The group retained, and in some cases improved, several important external rankings by leading global and regional agencies. Implats’ MSCI ESG Rating was upgraded to ‘A’ from ‘BBB,’ reflecting an improved approach to emissions and water management, and its strong governance structures. The group was also one of four JSE-listed metals and mining companies to be included in the S&P Global Sustainability Yearbook 2022 — and the only company, globally, awarded the Metals and Mining Industry Mover Award.

For the third consecutive year, Implats achieved an ‘A’ rating by the Carbon Disclosure Project for management of water security risk, a ‘B’ rating for climate change action and disclosures, and was included in the Bloomberg 2022 Gender-Equality Index. Implats remains a constituent of the FTSE4Good Index Series and the FTSE/JSE Responsible Investment Top 30 Index. All operations, bar Impala Canada, are ISO 14001:2015 certified, with three out of the five operations also ISO 45001:2018 certified. Impala Refineries holds the London Palladium and Platinum Markets Responsible Sourcing Standard certificate.

OPERATIONAL REVIEW

Implats navigated several operating challenges during the year. Extended safety stoppages, intermittent industrial action and power supply interruptions at Impala Rustenburg had a notable impact on production, while a storm-related provincial power outage and ongoing supply-chain and labour availability constraints hampered operational continuity at Impala Canada. Marula delivered record production in the period and Zimplats sustained production levels despite a complex operating environment and increased project activity.

Tonnes milled from managed operations decreased by 4%, to 22.36-million tonnes, with lower reported volumes at Impala Rustenburg and Impala Canada offsetting improved throughput at Marula and Zimplats.

Total 6E concentrate production of 3.17-million ounces was 4% lower and refined 6E production of 3.09-million ounces 6% lower.

Inflationary pressures from energy and consumables were compounded by the additional headcount and the payment of the previously signalled discretionary employee bonus in recognition of the strong financial performance in 2021. Total cash operating costs increased by 12%, with the impact of lower mined and refined volumes resulting in a 17% increase in unit costs to R17 364/6E oz.

Capital expenditure increased by 41% to R9.1-billion as investment accelerated across the mining and processing operations at Impala Rustenburg and several replacement and growth projects were initiated during the period.

Implats has six mining operations and its toll-refining business, Impala Refining Services. Its mining operations span the Bushveld Complex in South Africa, the Great Dyke in Zimbabwe and the Canadian Shield and include Impala Rustenburg, Zimplats, Marula, Impala Canada’s Lac des Iles, Mimosa and Two Rivers.

Implats employs more than 56 000 people across all operations and its metals, key to making many essential industrial, medical and electronic items, are key to a cleaner, greener world.

Implats actively develops markets for its PGM products, which are sold in South Africa, Japan, China, the US and Europe.