AFRICAN Chrome Fields (ACF), one of Zimbabwe’s biggest chrome miners, has revived the construction of its multi-million dollar aluminothermic plant, which had been frustrated by Covid-19 pandemic-induced lockdowns.

Tinashe Makichi

The project, which officials say will change Zimbabwe’s chrome beneficiation landscape, riding on the deployment of advanced technologies, is expected to be fully operational before the end of the year.

A visit by local publication businessdigest to ACF’s operations in Midlands revealed that contractors were back.

Officials said the project was expected to further increase the company’s range of products and boost employment across its operations.

The technologically-advanced plant will initially produce 300 tonnes of ultra-low carbon high grade ferrochrome per month, before doubling production to 600t when it reaches full capacity.

The production process will increase the economic value of the high-grade chromite ore by removing large quantities of gangue minerals, resulting in a higher grade ferrochrome with minimum impurities.

ACF mine manager Mark Beukes said efforts were underway to resume initial production as early as possible.

“This project was supposed to be up and running but the issue of Covid-19 affected a number of projects across the mining sector,” Beukes said. “So we have revived this project and as you can see all the equipment is on site and our engineers are working flat out to make this dream a reality.

“We believe this project has the capacity to change the chrome beneficiation landscape considering that this project is environmentally friendly and is not power intensive. This is all chemical reaction but the end product is of premium quality. This is a first of its kind in Africa and southern Africa to be specific.

“The project required between US$40 million and US$100 million to be fully complete and this has been expended and we are optimistic of the prospects of operationalising it. This project is a game changer,” he added.

The process used by the aluminothermic plant requires no electricity and gives ACF the opportunity to increase the economic value of the chromite it mines by way of beneficiation which will see the miner becoming a ferrochrome exporter.

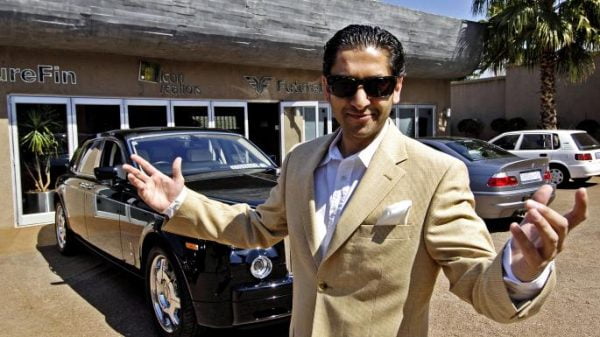

ACF, which is a mining unit under the Moti group, will double its production by 100% to 20 000t of chrome in the next two months from the current 10 000t as the diversified mining group targets a blitzkrieg in mineral production.

The mining company is targeting a massive revamp in mineral production at its Zimbabwean mining operations, which were affected by the two-year ravages of the Covid-19 pandemic.

Many governments around the world, including Zimbabwe, were forced into mandatory lockdowns that severely limited the movement of people in an effort to curb the spread of the disease.

Currently, the miner is operating four processing plants out of seven and there are heightened efforts to open plant Number 6, which is also the biggest in terms of capacity. That will see the company boosting its production to record levels.

In an attempt to meet the challenges of Covid-19, ACF was forced to rationalise its operations during 2020.

Towards the end of 2021, ACF was operating three of its seven sites but there has been a massive improvement following capital injection.

The diversified miner is also targeting other mining opportunities in lithium, platinum group metals and gold in Zimbabwe.

.png)