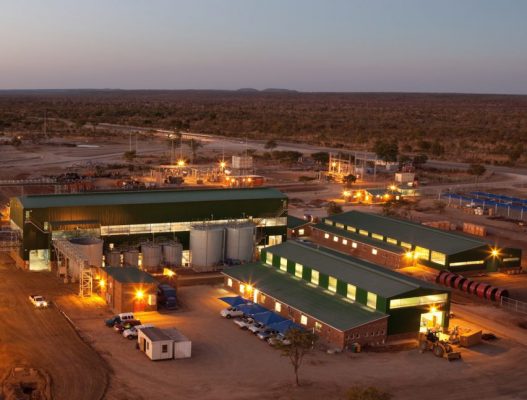

The country’s biggest platinum group metal (PGM) producer ZIMPLATS is moving with speed to ensure it further benefitiates matte to produce refined metallic products with about US$20 million used for the refurbishment of the mothballed Base Metal Refinery (BMR) at Selous Metallurgical Complex which has an estimated cost of US$200 million.

Rudairo Mapuranga

The base metal refinery that is being refurbished separates minerals like nickel, chrome and copper from platinum metal groups, but Zimplats says outdated technology makes it too expensive to run.

Zimplats’ BMR is designed to process an equivalent 5 200 tonnes of nickel and associated base metals contained in converter matte.

The company currently sends platinum concentrate to South Africa for processing, a development economic experts argue has prejudiced the country of potential revenue and jobs. This therefore means the Zimplats base metal refinery project resonates with the Government’s thrust on mineral beneficiation.

The government has over the years been exploring possible methods of ensuring the beneficiation of minerals, with policies targeting mostly platinum, diamonds, gold and chrome mining to unlock the full potential of the mining sector. Mineral beneficiation is in line with the Government’s quest for the country to achieve an upper-middle-income economy by 2030.

According to Zimplats Corporate Affairs Manager Busi Chindove equipment has been purchased and is on site with other equipment that has been purchased currently in transit as the PGM producer moves in to support government efforts for beneficiation of minerals.

Chindove said the current expenditure for the BMR project is about US$20 million with the project expected to cost nearly US$200 million.

“Some of the equipment has been purchased and is on site, other equipment has been purchased and is in transit. The current expenditure on the plant has been about US$20 million today,” Chindove said.

Speaking on the sidelines of a Ministerial visit to the mine on Friday, the Minister of Mines and Mining Development Hon Zhemu Soda said the government of Zimbabwe has identified value-addition and beneficiation across all sectors of the economy as key measures towards setting the economy on a sustainable growth path.

He said the move by Zimplats to refurbish BMR will bring value to the country’s PGM and also create jobs for the people.

“Metals must be beneficiated and added value before they exit our borders, the coming in of the BMR is obviously to add value to our minerals and also create jobs for our people,” Hon Soda said.

The project is part of the group’s overall capital investment strategy, which has a budget of US$1,8 billion to be implemented over 10 years beginning in 2021. Of the total investment, US$1,2 billion has already been approved for implementation.

Meanwhile, the group has committed millions to its major projects, which include mine development and upgrades at Mupani and Bimha, a 185 MW solar project, and base metal refinery refurbishment.

The mine development and upgrade projects at Mupani and Bimha are progressing according to plan. The projects to develop Mupani Mine and upgrade Bimha Mine will replace Rukodzi Mine, which was depleted in FY2022, and the Ngwarati and Mupfuti mines, which will be depleted in FY2025 and FY2028 respectively, millions have been spent on the projects.

Implementation of the 35 MW solar plant project progressed as planned with a cumulative US1 million spent on the project to date and US$35 million committed as of September 30, 2023 against a budget of US$37 million. This is the first of the project’s four phases which will be implemented at an estimated cost of US$2.9 million to generate 185 MW.

ZIMPLATS is Zimbabwe’s biggest mining company.