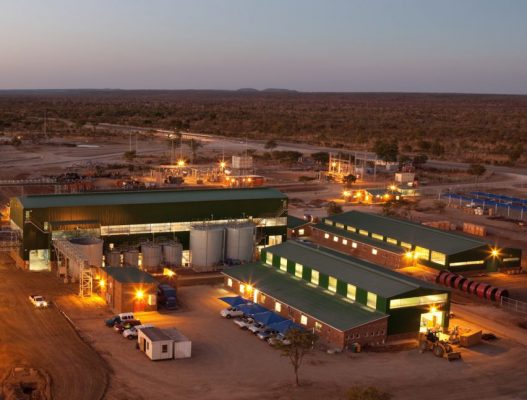

Zimbabwe’s largest platinum group metal (PGM) producer, Zimplats, has reached a significant milestone in its value addition and beneficiation strategy with the completion of its state-of-the-art smelter at the Selous Metallurgical Complex. This facility is set to enhance the production of critical base metals such as nickel, copper, and cobalt, contributing to the country’s broader mining industry objectives, Mining Zimbabwe reports.

By Rudairo Mapuranga

During a ministerial visit led by the Minister of Mines and Mining Development, Hon. Winston Chitando, Zimplats’ Chief Technical Officer, Amend Chiduma, highlighted the operational capabilities and significance of the newly completed smelter. He emphasized that this development ushers in an era of increased local processing for Zimplats.

“We receive concentrates from our concentrators. Once the concentrates arrive here, they are wet and require drying before entering the furnace. The flash dryer, part of our advanced smelting technology, ensures efficient drying of the PGM concentrates,” Chiduma explained.

The smelter operates at 38 megawatts and boasts an annual processing capacity of 380 kilotons, tripling the company’s previous capacity. “This smelter is located adjacent to our old facility, and its furnace is among the largest globally. With this upgrade, we’ve increased our smelting capacity threefold,” Chiduma noted.

Smelting Process Details

Chiduma outlined the stages involved in the smelting process:

- After concentrates are fed into the furnace, furnace matte is produced.

- The matte undergoes further refinement in converters to eliminate impurities.

- Supporting infrastructure, including cooling towers and electrical switchgear facilities, ensures seamless operations.

The completion of the smelter reduces Zimplats’ reliance on external smelting services and aligns with its strategy of maximizing local beneficiation while boosting production and export capacity.

Base Metal Refinery (BMR) Construction Progress

In addition to the smelter, Zimplats is making progress on its Base Metal Refinery (BMR), which will complete the beneficiation process by refining nickel, copper, and cobalt extracted from the smelter.

“We’ve procured all required circuits for the BMR and are now assembling and commissioning them. This will enable full beneficiation, adding value to both the company and the country,” Chiduma said.

Investment in Sulphuric Acid Production

Zimplats is also investing in an acid plant that will utilize gases emitted by the smelter to produce sulphuric acid, a key component in fertilizer production. This will support Zimbabwe’s agricultural sector by meeting growing fertilizer demands.

Significance for Zimbabwe’s Economy

The advancements at the Selous Metallurgical Complex are pivotal in Zimbabwe’s economic growth strategy, which aims to achieve upper-middle-income status by 2030. Zimplats’ investments in local beneficiation and refining processes are expected to play a critical role in industrialization and economic growth.

These developments underline Zimplats’ commitment to aligning its operations with Zimbabwe’s national economic goals, fostering both industrial and agricultural progress.

.png)